ELECTRO HYDRAULIC ACTUATOR

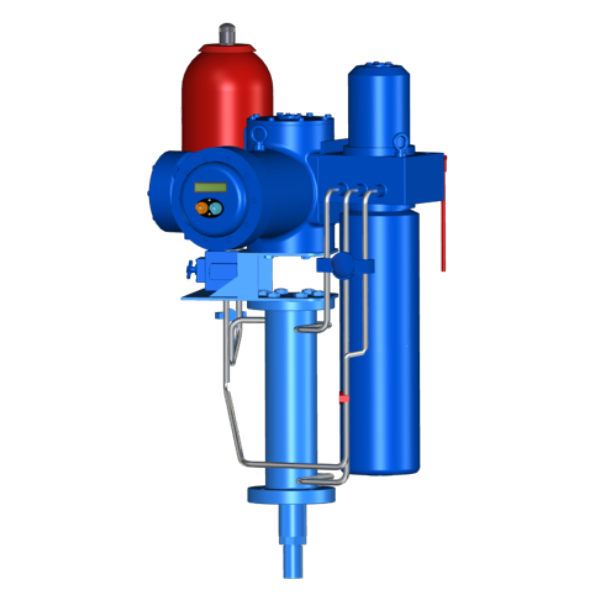

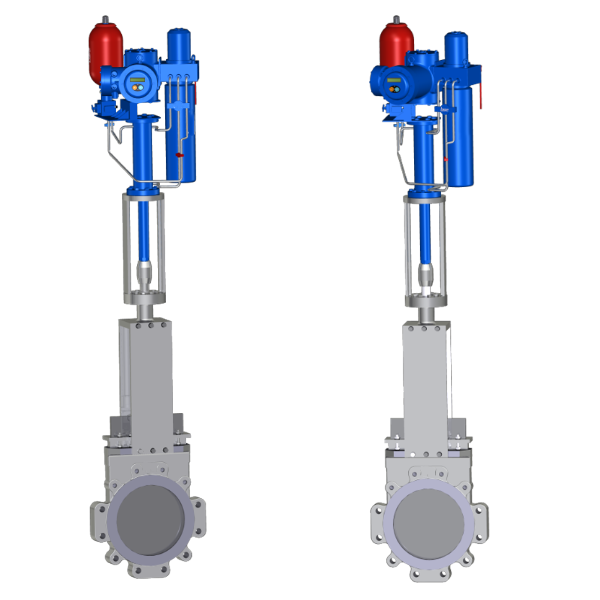

BSE-EHA-DL/DR

Double Acting Linear Actuator

Series BS-EHA-DL

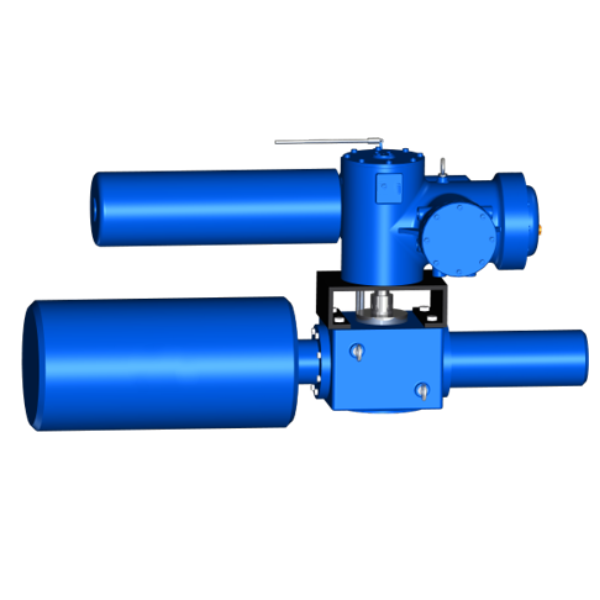

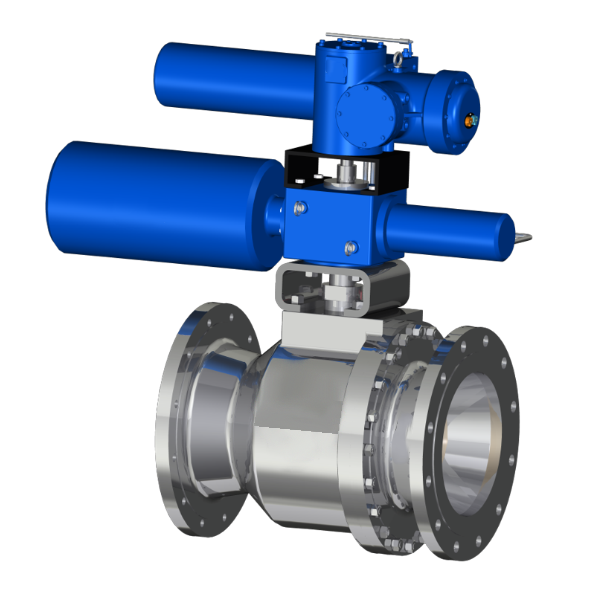

Double Acting Rotary Actuator

Series BS-EHA-DR

Self-contained electro-hydraulic operator’s general specifications

1. Linear and rotary (quarter-turn) valve actuators

2. Double-acting and single-acting (spring-return)

3. On-off/isolation, positioning, and continuous modulation service

4. Hydraulic fluid as the driving medium

5. Fluid power can be direct motor driven, spring-return, motor pressure driven, or accumulator power driven

6. Requires only electric power and a control signal to operate

7. Includes electronic controls and a dedicated power unit

Modular package contains the following features

1. Compact motor

2. Single direction pump with reservoir

3. Control Solenoid valve/manifold

4. On/Off, Auto/Manual, and Close/Stop/Open selector switch

5. Power unit with oil reservoir

6. Position transducer with limit switches

7. Non-hazardous enclosure available

- OPTIONAL FEATURES

- Low power PLC

- Hazardous / Explosion proof enclosure

- Larger Size Accumulator

- Valve positioner

- Control protocol conversion module

- Hand pump for manual override

- UNIQUE FEATURES FOR ON-OFF SYSTEM

- Linear ESD speed < 1 sec for 50 mm travel

- Rotary ESD speed < 1 sec

- Rotary system has built in transmitter

- UNIQUE FEATURES FOR MODULATING

- < 0.05 % using Proportional or Servo valves

- Linear Positioning speed up to 0.2 sec per 25 mm

- Rotary positioning speed up to 0.8 sec for 90°

- CONTROL FEATURES

- The selector switch can be used for setting local/remote selection and open/close. Allows manual operation.

- The red selector enables the operator to choose remote control, local control function and stop during operation.

- This selector switch can be locked in each position.

- PRESSURE MONITORING

- Actuator torque/force is measured based on pressure.

- Pressure transducer is integrated inside the hydraulic control system.

- Real time feedback from the pressure transducer is recorded and diagnostics information is generated based on parameterization.

- It can detect over pressure, low pressure, "valve stuck", hydraulic failure, etc if any.

- 4-20 mA feedback signal proportional to actual torque of the valve is available as an option.

- FAILSAFE OPTION

-

Failsafe action can be performed based on following

1. On loss of ESD signal or ESD demand occurs

2. On loss of main power supply. In applications where main power is part of SIS.

- In both the above cases, the valve will be driven to its failsafe position in case of failure of main power supply or ESD demand

- ESD Input signal - 20 to 60 VDC or 60 to 120 VAC, 110 to 220 VAC.

- FAIL FREEZE OPTION

- Main power supply is unreliable and is not part of functional safety.

- On failure of main power supply the operation of the actuator or the valve position is unaffected.

- ESD solenoid valve is separately powered through a 24 VDC ESD input signal and is solely responsible for safety function.

- CONTROL LAYOUT

- Strong and reliable electronics architecture.

- Epoxy painted to ensure long life against moisture ingress.

- Hardware, software are well proven using methodology software, validation software to avoid bugs and infinite loops.

- All integration goes through stringent quality checks to ensure long life.

- Potential free relays to support outputs and alarm configurations

- PARTIAL STROKE TEST

- Partial stroke test (PST) is a method to check, detect and ensure availability of safety function on demand. PST physically moves the valve to a predefined position, without affecting or disturbing the current process requirement.

- Partial stroke test can prevent unexpected failure of safety function and provides information on current health status of valve and actuator

- GENERAL FEATURES

- Completely self-contained. Single hydraulic block, no additional tubing between various hydraulic blocks.

- Modular design, for Linear, Rotary, On-off or Modulating.

- Fail close, or open by spring or using accumulator.

- Fail freeze function is achieved by using double acting actuator.

- ESD variants, logical or hard wired.

- Partial stroke through remote or using local panel.

- Full featured LCD for ease of installation, commissioning and operations.

- Linear thrust up to 8,000 KN.

- Water and dust tight, IP 68 ( 10 m, 96 hour ).

- Monolithic, Weather proof or Ex d enclosure.

- Extended diagnostics for analysis available on network.

- Parametric setting for various applications.

- Operating temperature, -50 °C to +70 °C.

- Local mechanical indication can be provided as an option.

- Shatterproof polycarbonate dome for visibility.

- Two piece unique indicator, ensures a life long visibility.

- 2 LEDs (red/green) indicate the position (close/open) at ends of travel, 3rd LED, Blue for faults.

- During operation, LED blinks depending on open or close cycle.

- Red and green LED can be freely assigned to open or closed positions.

- Stroke up to 1m.

- Speed up to 0.2 sec for 25mm..

- Position feedback of 4-20mA, 0-10V optional.

Communication

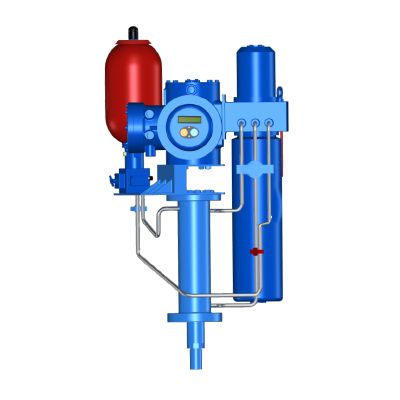

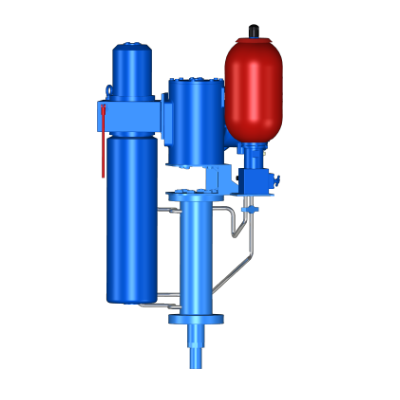

Views

-

FRONT

-

BACK

Certification

| ATEX- II 2 G EEx de* IIB T4 (Tamb -50 to +60 °C) |

|

EN60079-0, EN60079-1, EN60079-7, EN13463-1 INMETRO:BR-Ex de IIB T4 (Tamb -20 to +60 °C) INMETRO:BR-Ex de IIC T4 (Tamb -40 to +60 °C) Certification temperatures are not operating temperatures. |

| SAFETY INTEGRITY |

|

Designed to SIL 3. |

| ENCLOSURE |

|

Watertight to IP67 / NEMA 6, double-sealed protection with separate cable gland and termination compartments. Optional to IP68 (7 meters / 72 hours). Consult factory for alternative depth / pressures. |