PNEUMATIC SCOTCH YOKE ACTUATORS

OUR ACTUATORS

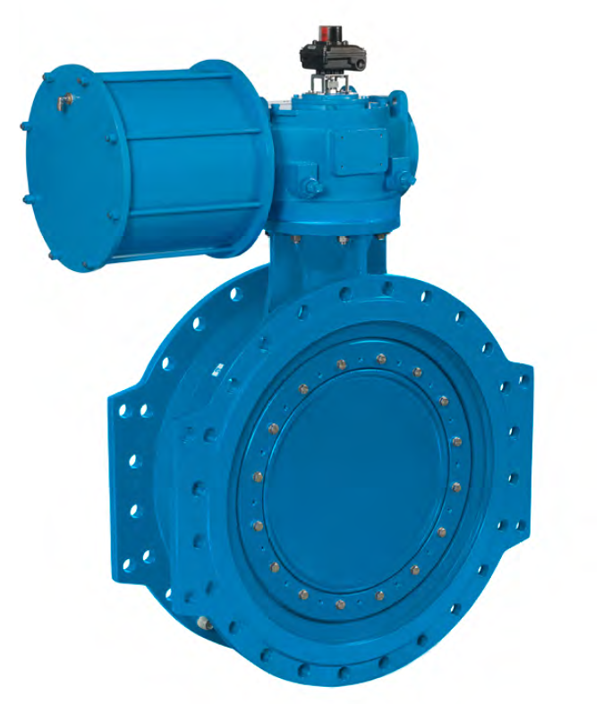

Product offerings include scotch yoke aluminum housed actuators for heavy duty service with torque values up to 2.2 million in-lb (250,000 Nm). BSE products offer reliable and dependable automation for quarter turn valves.

Engineered and built to withstand most applications and environmental conditions, the precision design and quality of our actuators provide long and safe performance for valve control.

Primary amongst the targeted market segments are the following:

• Chemical and Petrochemical

• Food and Beverage

• Heating, Ventilation and Air Conditioning

• Marine

• Mining

• Oil and Gas

• Original Equipment Manufacturing

• Pulp and Paper

• Semiconductor

• Water and Wastewater

EFFICIENCY AND LONG LIFE

Every BS-SY Series actuator is built to provide long end efficient service with minimum maintenance. The design, engineering and materials used in their construction ensure optimum performance even in the harshest environments.

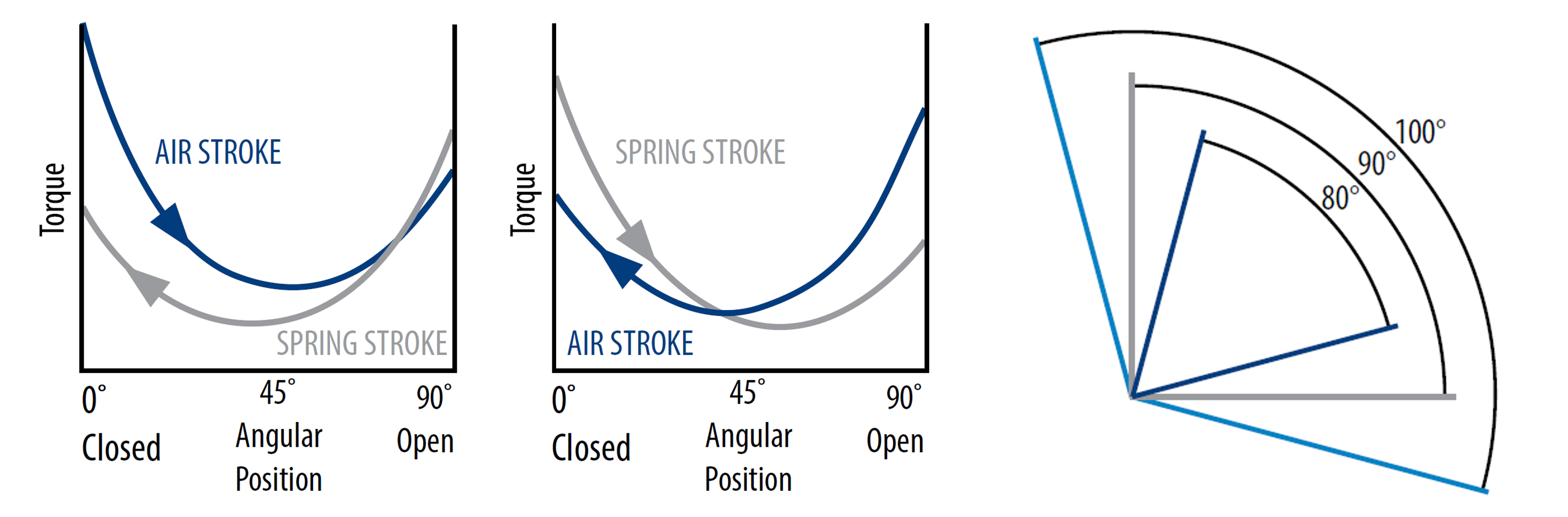

BS-SY Series actuators are available with symmetric yokes. Symmetric yokes provide more constant torque throughout at both the break points and end positions.

BS-SY Series of actuators are provided with bidirectional pinion travel stops. Bidirectional travels stops allow for ±10° travel adjustment between 80° to 100°. These travel stops help to absorb impact loads associated with recommended travels speeds and prolong valve seat integrity.

FLEXIBLE CONFIGURATIONS

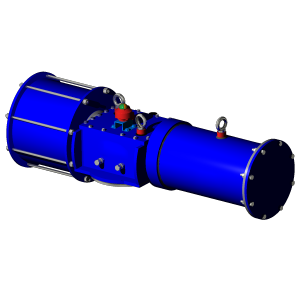

BS-SY Series actuators are manufactured in many different combinations of actuator sizes, cylinder diameters, and designs. Both the double acting (DA) or spring return (SR) designs are available for installation on ¼ turn valves such as ball, butterfly and plug valves. BS-SY actuators are designed for use over a wide range of pressures or temperatures.

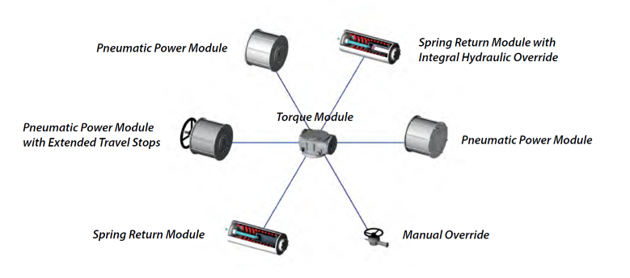

The BS-SY actuator is a modular design. A pneumatic or hydraulic cylinder can be attached to either side or both sides. With a large stock of finished and semi-finished components always available, actuators can be assembled and supplied with very fast and reliable deliveries

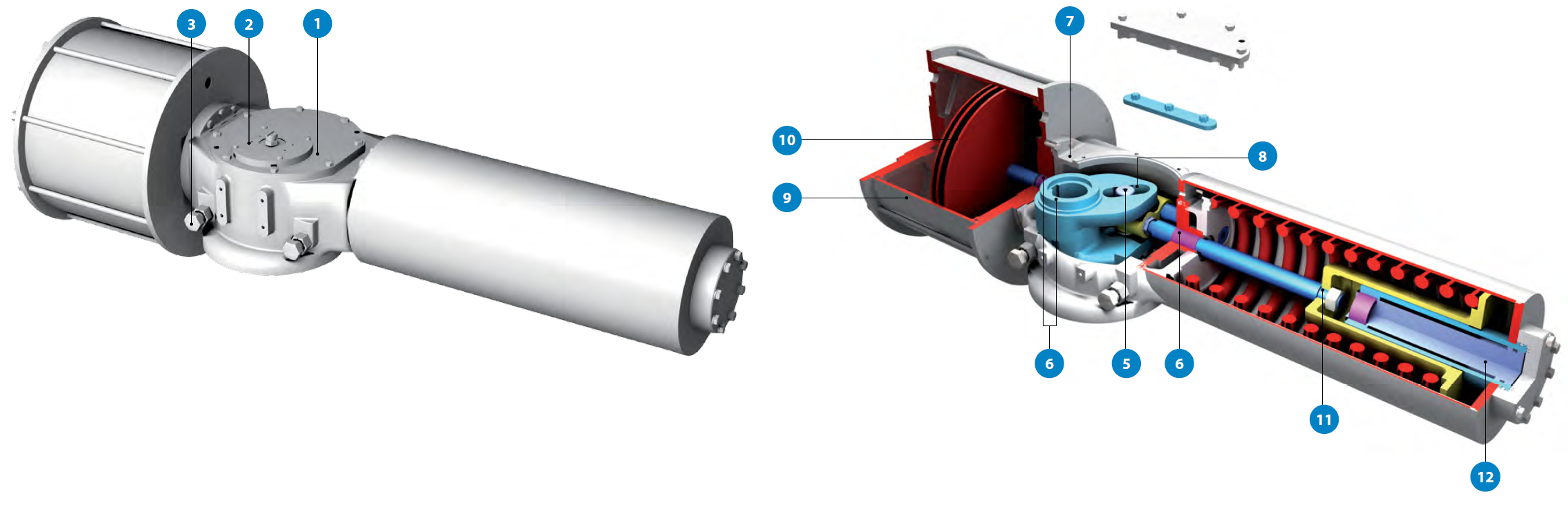

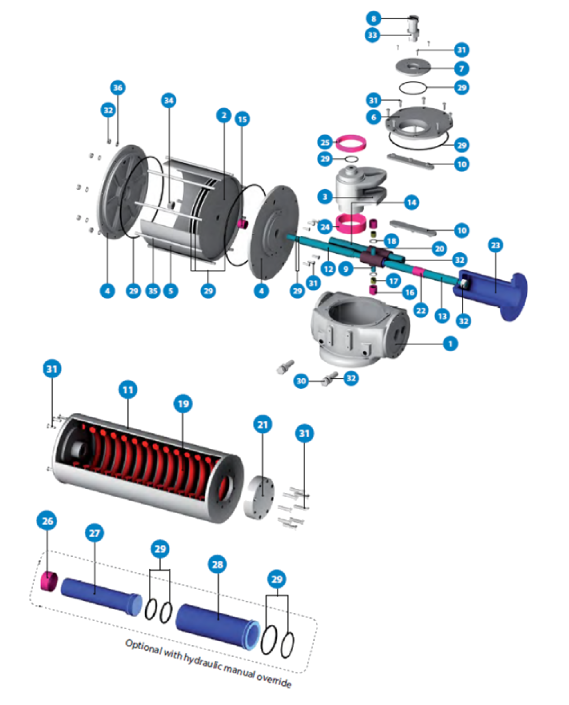

DESIGN FEATURES

BODY

INTERNAL BODY

PNEUMATIC CYLINDER

SPRING MODULE

10 different sizes from F10 (4416 in-lb/500 Nm) up to F60 (2.2 million in-lb/250,000 Nm.)

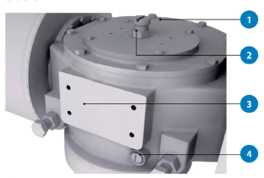

1. Internal O-Rings to ensure water ingress protection.

2. NAMUR Standard for all sizes for assembly of switch boxes and positioners.

3. Threaded parts in front and the back side of the body for easy assembly of a pneumatic control panel.

4. Vent check valve releases overpressure at the center body while preventing the ingress of gas, corrosive elements and water.

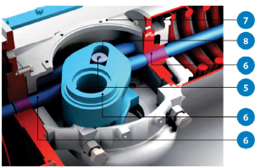

5. Dual roller type pinion reduces the friction between the yoke arm and pin, minimizing the wear.

6. Sintered Teflon metallic bearings protect the sliding and rotating components, suitable for either dry or lubricated working conditions.

7. PTFE thrust bar prevents yoke pin axial movement, transferring axial loads directly to the drive module case.

8. Guide block connects the piston rod with the pinion, and compensates for side load deflection thereby reducing wear on rod, bearings and seals.

9. PNEUMATIC CYLINDER - The inner surface of cylinder is coated with Sintered Teflon to reduce friction.

10. PISTONS SEALS - Double sealing, with O-Ring and dynamic ring to prevent metal to metal contact between the piston and the cylinder.

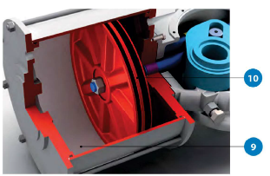

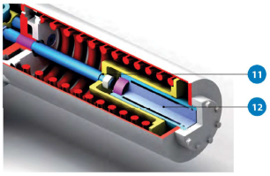

11. SPRING MODULE - Safe spring lock prevents spring module detachment from the drive module.

12. HYDRAULIC OVERRIDE - Internal hydraulic cylinder for manual pump override.

MATERIAL SPECIFICATIONS

| ITEM | DESCRIPTION | MATERIAL |

| 1 | Body | Ductile Iron (LF6) |

| 2 | Piston | Ductile Iron (LF6) |

| 3 | Yoke | Carbon Steel (LF6) |

| 4 | End Caps | Carbon Steel (LF6) |

| 5 | Pneumatic Cylinder | Carbon Steel (LF6) |

| 6 | Body Cover | Ductile Iron (LF6) |

| 7 | Shaft Cover | Ductile Iron (LF6) |

| 8 | Drive Shaft | Stainless Steel (Stainless Steel) |

| 9 | Pin | Alloy Steel (17-4 PH) |

| 10 | Guide Strips | PTFE (PTFE) |

| 11 | Spring Cylinder | Carbon Steel (LF6) |

| 12 | Center Bar | Alloy Steel Chromium Plated (17-4 PH) |

| 13 | Tension Rod | Alloy Steel Chromium Plated (17-4 PH) |

| 14 | Center Guide Bar | Alloy Steel Chromium Plated (17-4 PH) |

| 15 | Sliding Bearing | Carbon Steel + PTFE (Carbon Steel + PTFE) |

| 16 | Roller Sliding Bearing | Carbon Steel + PTFE (Carbon Steel + PTFE) |

| 17 | Roller | Carbon Steel + PTFE (Carbon Steel + PTFE) |

| 18 | Block Washer | Stainless Steel (Stainless Steel) |

| 19 | Spring Cylinder | Alloy Steel (50CrV) |

| 20 | Guide Block | Carbon Steel + PTFE (LF6) |

| 21 | Cover Plate | Carbon Steel (LF6) |

| 22 | Sliding Bearing | Carbon Steel + PTFE (Carbon Steel + PTFE) |

| 23 | Spring Seat | Carbon Steel (LF6) |

| 24 | Sliding Bearing | Carbon Steel + PTFE (Carbon Steel + PTFE) |

| 25 | Sliding Bearing | Carbon Steel + PTFE (Carbon Steel + PTFE) |

| 26 | Sliding Bearing | Carbon Steel + PTFE (Carbon Steel + PTFE) |

| 27 | Piston | Carbon Steel (LF6) |

| 28 | Hydraulic Cylinder | Carbon Steel (LF6) |

| 29 | O-Ring1 | NBR (Silicone) |

| 30 | Adjustment Screw | Carbon Steel (Stainless Steel) |

| 31 | Screw | Stainless Steel (Stainless Steel) |

| 32 | Nut | Stainless Steel (Stainless Steel) |

| 33 | Nut Drive Shaft | Stainless Steel (Stainless Steel) |

| 34 | Center Bar Nut | Carbon Steel (Stainless Steel) |

| 35 | Screw | Carbon Steel (Stainless Steel) |

| 36 | Gland Nut | Carbon Steel (Stainless Steel) |

| PNEUMATIC SCOTCH YOKE MODELS | |

| DOUBLE ACTING ACTUATOR | DA |

| SPRING RETURN ACTUATOR | SR3 |

| SR4 | |

| SR5 | |

| SR6 | |